General Air Products Air Compressors

General Air Products fire protection air compressors for dry pipe and pre-action type sprinkler systems. Specifically designed to meet the unique demands of a fire sprinkler application and requirements in NFPA 13 for both fill up time ( NFPA 13 7.2.6.2.2 ) and water delivery time ( NFPA 13 7.2.3.6.1 ).

General Air Products Air Compressors Brochure PDF

Request InformationDescription

General Air Products fire protection air compressors for dry pipe and pre-action type sprinkler systems. Specifically designed to meet the unique demands of a fire sprinkler application and requirements in NFPA 13 for both fill up time ( NFPA 13 7.2.6.2.2 ) and water delivery time ( NFPA 13 7.2.3.6.1 ).

General Air Products is synonymous with fire protection air compressors for dry pipe sprinkler systems and for good reason. We have been the leader in the fire sprinkler industry since we began building fire protection air compressors in the 1960s. Most commonly used in dry pipe and pre-action type sprinkler systems, we offer a complete range of air compressors that are specifically designed to meet the unique demands of a fire sprinkler application.

Air Compressor Options:

Click to jump to full details including Data Sheets and Technical Specifications.

Oil Less, Riser Mounted OL Plus Series

General Air Products’ newly improved OL Plus Series Oil Less Riser Mounted Fire Protection Air Compressors are the same compressors the fire sprinkler industry has come to rely on but with 30 years’ worth of experience based improvements built in!

Oil Less, Tank Mounted OLT Plus Series

General Air Products’ has improved our tank mounted oil less fire protection air compressor offering as well – now referred to as the OLT Plus series.

Quiet Air Compressors, Q Series

The Q series is our newly developed line of quiet fire protection air compressors that directly address noise issues.

Lubricated, Tank Mounted LT Plus Series

LT Plus Series is specifically engineered to pressurize dry pipe and pre-action sprinkler systems according to the parameters of NFPA 13. Tank mounted air compressors are recommended as the ideal type of compressor for dry pipe sprinkler applications.

Lubricated, Base Mounted L Plus Series

The L Plus Series base mounted, oil lubricated fire protection air compressors are a rugged, old school style, workhorse of an air compressor.

Dry Air Pac Dryer Packages DAP Series

The only FM Approved, twin tower regenerative dryer / compressor package designed for the fire sprinkler industry. Provides moisture free air, assuring that there are no ice plugs in freezer room applications and that corrosion is significantly reduced in any dry or pre-action sprinkler system.

Oil Less Air Compressors

Oil Less Riser Mounted Air Compressors

GAP Air Compressors Riser Mounted Standard Data Sheet PDF

GAP Air Compressors Riser Mounted Low Pressure Data Sheet PDF

General Air Products’ newly improved OL Plus Series Oil Less Riser Mounted Fire Protection Air Compressors are the same compressors the fire sprinkler industry has come to rely on but with 30 years’ worth of experience based improvements built in! All of our OL Plus single phase standard units and low pressure units are UL 1450 listed for fire protection, fully automatic, and virtually maintenance free. We have added a 30” braided stainless steel flex hose to the riser mounting kit and pressure switch that were already included to allow for a fast and easy installation. Our standard OL Plus series units are single phase, pre-wired adjustable up to 60 psi and factory pre-set. Low pressure, High pressure, 3 phase and 50 Hz OL Plus Series units are available. While we do include a riser mounting kit these units can be wall or floor mounted as well.

Range: The OL Plus Series fire protection air compressors cover 30 minute fill up times on sprinkler systems up to 1225 gallons in size.

What’s Included:

- Oil less piston air compressor

- New 30” stainless steel flex hose

- New Improved riser mounting kit

- UL Listed pressure switch

- Bubble tight air check valve

- ASME Pressure Safety Valve

- Air intake filter(s)

Available As:

- Single Phase (Standard) (pre-set for 40 psi off)

- Three Phase

- Low Pressure (pre-set for 18 psi off)

- High Pressure (pre-set for 100 PSI)

- 50 Hz (electrical current for use outside of the USA)

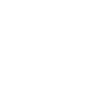

Technical Specifications – Standard Single Phase Units

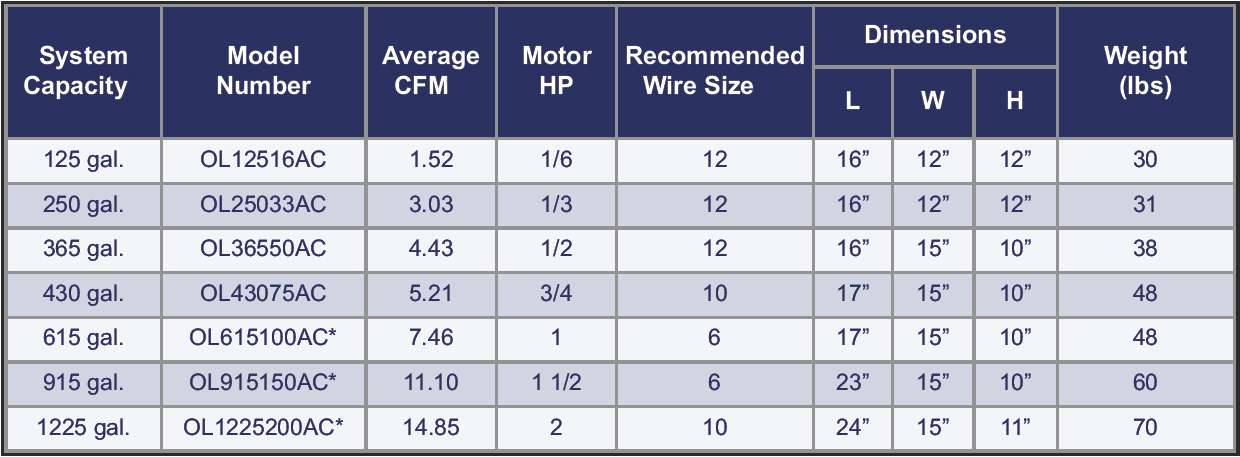

Technical Specifications – Low Pressure Single Phase Units

Oil Less Tank Mounted Air Compressors

GAP Air Compressors Tank Mounted Standard Data Sheet PDF

General Air Products’ has improved our tank mounted oil less fire protection air compressor offering as well – now referred to as the OLT Plus series. Standard single phase units are UL 1450 listed for fire protection and integrally mounted on ASME air receivers. We have improved the durability, reduced noise and simplified installation with the inclusion of a 30” braided stainless steel flex hose and 4 vibration isolation pads.

Tank mounted oil less air compressors are recommended air the ideal air compressor type for dry pipe sprinkler system applications. We highly recommend a tank mounted compressor when an accelerator is required on the dry pipe sprinkler system. Our standard OLT Plus series units are single phase, pre-wired with pressure factory pre-set and adjustable up to 60 PSI. High pressure, 3 phase and 50 Hz OLT Plus units are also available.

Range: The OLT Plus Series fire protection air compressors cover 30 minute fill up times on sprinkler systems up to 1225 gallons in size.

Note: Each individual system requires an air maintenance device (Model AMD-1) per NFPA 13. Multiple dry valves may be supplied from a single tank mounted air compressor when using our AMD-1 air maintenance devices.

What’s Included:

- Oil less piston air compressor

- ASME Coded pressure vessel

- New Vibration isolation pads (4)

- New 30” stainless steel flex hose

- UL Listed pressure switch

- Bubble tight air check valve (seated in tank)

- Air Pressure Gauge

- ASME Pressure Safety Valve

- Manual Tank Drain

- Air intake filter(s)

Available As:

- Single Phase (Standard) (pre-set for 40 psi off)

- Three Phase

- High Pressure (pre-set for 100 PSI)

- 50 Hz (electrical current for use outside of the USA)

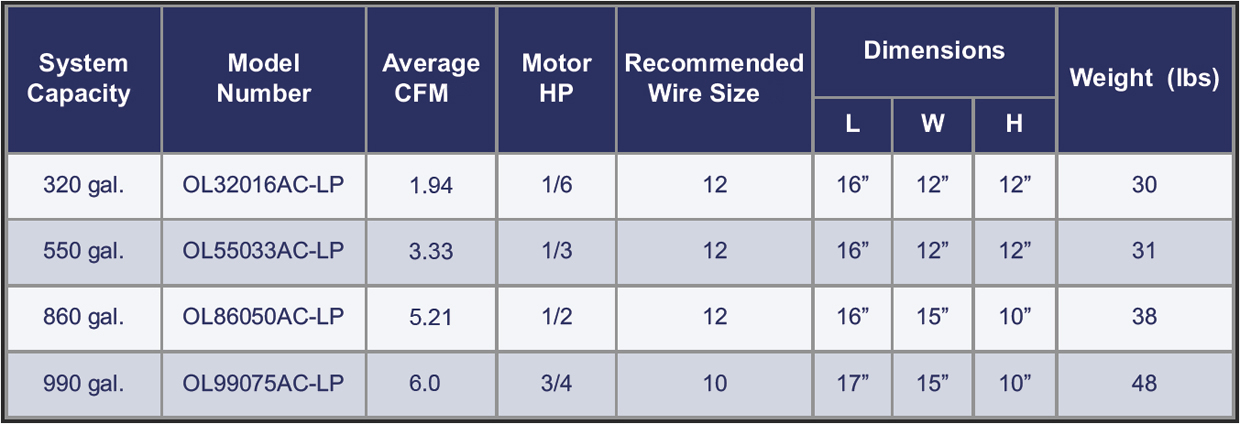

Technical Specifications – Single Phase Units

Quiet Oil Less Air Compressors

GAP Air Compressors Q Series Data Sheet PDF

Over the years changes in building designs have led to all types of cost savings and space efficiencies but they have also caused new problems to come to light. Many newer buildings no longer have equipment rooms or utility areas. Instead the equipment meant for these spaces – like fire protection air compressors – have been moved right in the middle of offices, right next to bedrooms in hotels or right behind choirs in churches. Our air compressors didn’t get loud, they got installed in occupied spaces.

The Q series is our newly developed line of quiet fire protection air compressors that directly address noise issues. This completely redesigned Oil Less line is capable of filling systems up to 250 gallons in 30 minutes and maintaining pressure on systems up to 2,000 gallons

Applications:

- Hospitals

- Nursing Homes

- Hotels

- Offices

- Golf Courses

- Museums

- Schools / Universities

- Libraries

- Labs

- Server Rooms

- Preaction Systems

- Any environment where sound is an issue

Construction Features:

- Significant Decibel Reduction

- Oil Less Piston Compressor

- Permanently Lubricated Bearings

- Fully Automatic, Direct Drive

- Thermal Overload Protection

What’s Included:

- UL Listed, Pre-Set Pressure Switch

- 30” Stainless Steel Flex Hose & Union

- Mounting Bracket Kit (Riser Mount)

- Vibration Pads (Tank Mount)

- Integrated Air Intake Filter

- ASME Pressure Safety Valve

- Bubble Tight Air Check Valve

- Lifetime Customer Service & Tech Support

Available As:

- Standard Riser Mount (pre-set for 40 PSI off)

- Standard Tank Mount (pre-set for 40 PSI off)

- Low Pressure Riser Mount (pre-set for 18 PSI off)

- High Pressure Riser Mount (max pressure 100 PSI)

- High Pressure Tank Mount (max pressure 100 PSI)

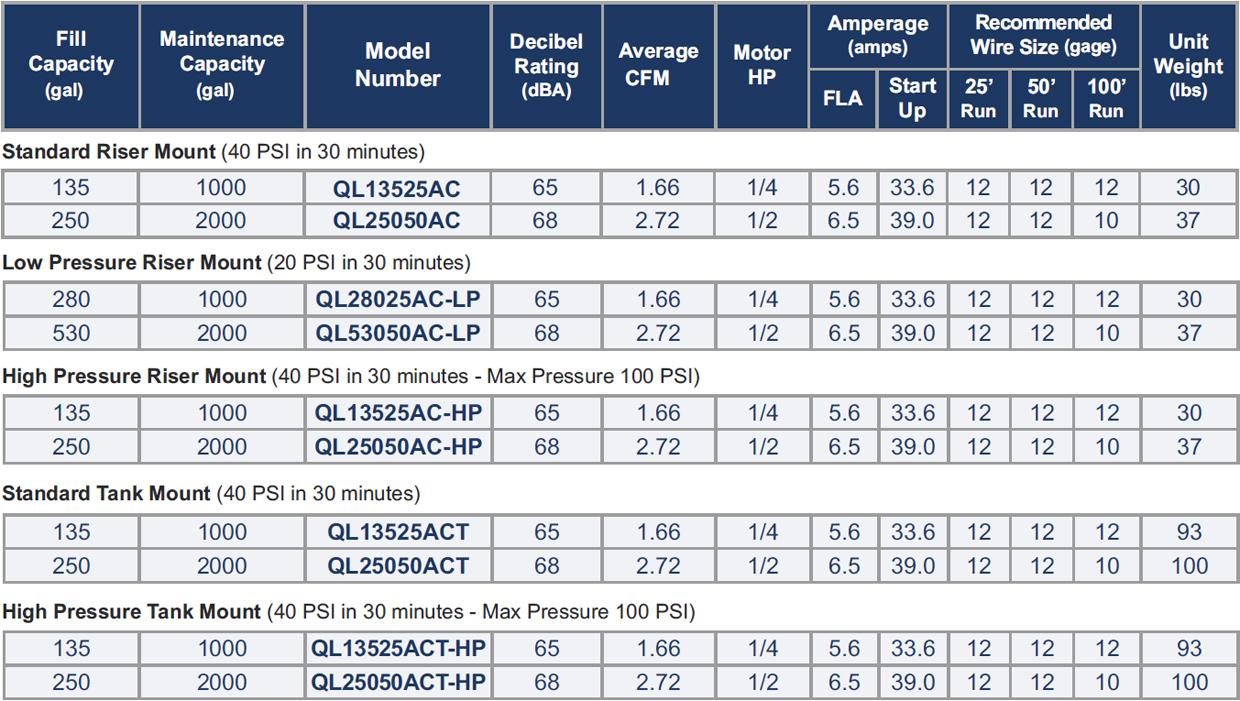

Technical Specifications

Lubricated Air Compressors

Lubricated Tank Mounted Air Compressors

GAP Air Compressors Lubricated Tank Mounted Standard Data Sheet PDF

General Air Products’ LT Plus Series tank mounted lubricated air compressors are integrally mounted on ASME coded air receivers. They arrive ready for installation with a quart of compressor oil and a mounted pressure switch. Single phase, three phase, high pressure and 50 Hz units are available.

As with all of our fire protection air compressors, the LT Plus Series is specifically engineered to pressurize dry pipe and pre-action sprinkler systems according to the parameters of NFPA 13. Tank mounted air compressors are recommended as the ideal type of compressor for dry pipe sprinkler applications. We highly recommend a tank mounted air compressor where an accelerator is in use (see our model OLRTK for an alternative).

Range: The LT Plus Series lubricated, tank mounted fire protection air compressors can be used in dry sprinkler systems up to 2500 gallons in size.

Note: An AMD-1 air maintenance device is required by code with all tank mounted fire protection air compressors. Multiple dry valves (no more than 3) may be supplied from a single tank mounted compressor when using our AMD-1 on each individual system.

What’s Included:

- NEMA Rated / UL Listed Motor

- Industrial Duty Compressor Pump

- ASME Coded Pressure Vessel

- UL Listed Pressure Switch

- Flywheel and Belt

- Bubble Tight Air Check Valve (seated in tank)

- Air Pressure Gauge

- ASME Safety Valve

- Manual Tank Drain

- 1 QT compressor oil (shipped loose)

- 30” Stainless Steel Flex Hose (NEW)

- Vibration Isolation Pads (NEW)

Available As:

- Single Phase

- Three Phase

- High Pressure (100 PSI)

- 50 Hz (electrical current for use outside of the USA)

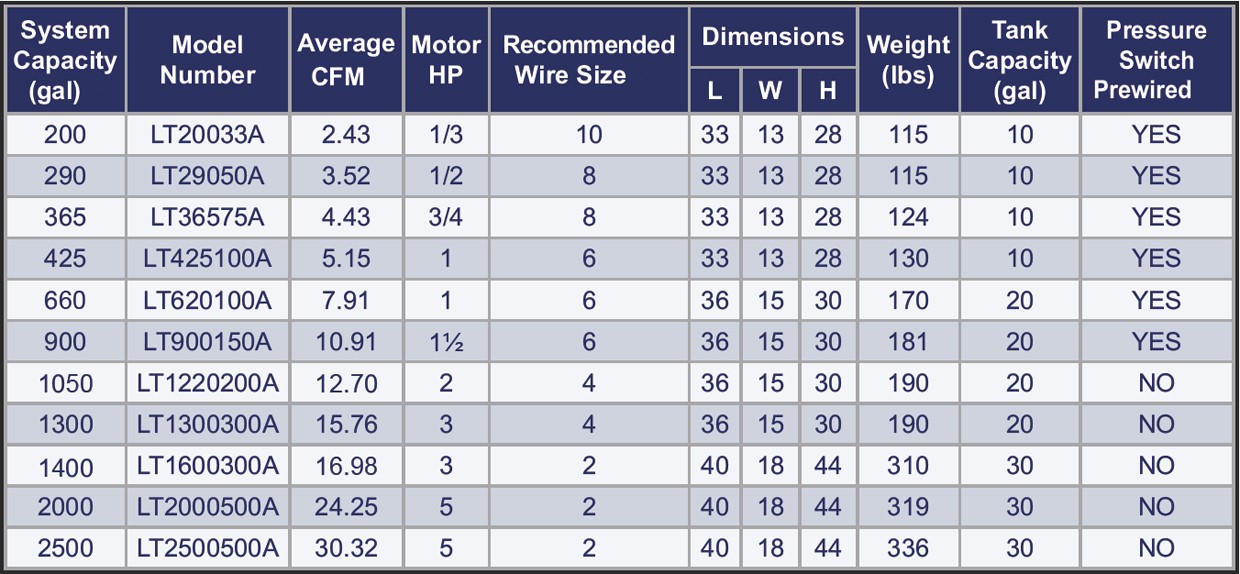

Technical Specifications – Standard Single Phase Units

Lubricated Base Mounted Air Compressors

GAP Air Compressors Lubricated Base Mounted Data Sheet PDF

The L Plus Series base mounted, oil lubricated fire protection air compressors are a rugged, old school style, workhorse of an air compressor. Single phase, three phase, high pressure and 50 Hz units are available. As with all of our fire protection air compressors, the L Plus Series is specifically engineered to pressurize dry and pre-action sprinkler systems according to the parameters of NFPA 13.

Range: The L Plus Series lubricated, base mounted fire protection air compressors can be used in dry sprinkler systems up to 2500 gallons in size.

Note: L Plus Series units do not include a pressure switch. Automatic operation requires the separate purchase of an AMD-2 air maintenance device.

What’s Included:

- NEMA Rated / UL Listed Motor

- Industrial Duty Compressor Pump

- Flywheel and Belt

- Pressure Relief Valve (shipped loose)

- Air Intake Filter

- 1 QT compressor oil (shipped loose)

- 30” Stainless Steel Flex Hose (NEW)

- Vibration Isolation Pads (NEW)

Available As:

- Single Phase (60 psi, Standard)

- Three Phase

- High Pressure (100 PSI)

- 50 Hz (electrical current for use outside of the USA)

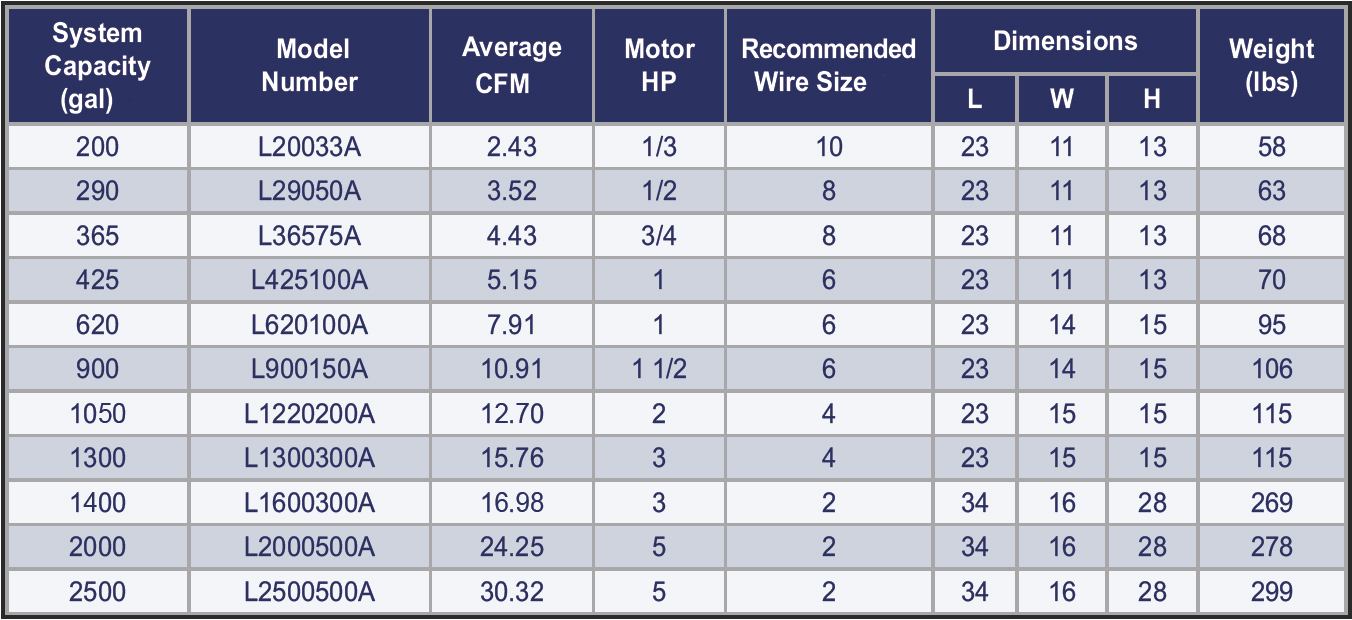

Technical Specifications – Standard Single Phase Units

Dry Air Pac Air Compressor Dryer Packages

GAP DAP Dry Air Pac Air Compressor Dryer Packages Data Sheet PDF

General Air Products DAP Series Dry Air Pac Air Compressor Dryer Packages

FOR CORROSION MITIGATION AND FREEZER ROOM APPLICATIONS

FM Approved Dry Air Pac® Air Compressor / Air Dryer Package for Applications where Moisture Removal is Essential

General’s DAP Series Dry Air Pac® is the only FM Approved, twin tower regenerative dryer / compressor package designed for the fire sprinkler industry. This turnkey package provides moisture free air, assuring that there are no ice plugs in freezer room applications and that corrosion is significantly reduced in any dry or pre-action sprinkler system.

The Dry Air Pac® has been the sprinkler industry’s benchmark for nearly 30 years in cold storage, freezer room facilities and other installations where moisture removal is essential. Dry air has long been utilized to prevent ice plugs from forming and in the same process reducing pipe corrosion significantly.

By bringing the pressure dew point of the air inside of the sprinkler piping system down to a -40 degree F dew point (note that this is a moisture measurement, not the temperature inside the pipe) moisture is removed from the compressed air supplying the sprinkler system and the process of oxidation is being controlled. In short, this means no ice plugs and significant corrosion protection.

Dry air, maintained at a -40 degree dew point or better is an alternative to corrosion mitigation offered from nitrogen generators. Corrosion can be an expensive issue to deal with as dry pipe sprinkler systems age, but not all systems are best served with a more sensitive nitrogen generator.

How Does it Work?

Everything starts with the air compressor – be it dry air or nitrogen. The air compressor on the Dry Air Pac® is designed to fill the sprinkler system with -40 to -60 degree F dew point air in 30 minutes in accordance with NFPA 13 standards, as well as provide the pressure needed to allow the air dryer to function properly.

Prior to entering the desiccant beds, an air-cooled aftercooler cools the compressor’s hot discharge air. A coalescing pre-filter with differential pressure gauge removes oil vapor and other contaminants that can destroy the desiccant in the dryer towers. A combination particulate filter and regulator prevents downstream migration of desiccant dust while regulating air pressure to the sprinkler system.

The super-absorbent desiccant and the accompanying filters ensure that the compressed air entering the piping network is dried to a -40°F to -60°F Dew Point. Up to -100°F Dew Point is achievable.

At this point the compressed air is dry and it will not introduce moisture into the sprinkler system – this is how the Dry Air Pac® has been used effectively to prevent ice plugs in systems where freezing temperatures come into play, i.e. freezer rooms.

When the dry air enters the sprinkler pipe it “picks up” any residual moisture inside the pipe. Water molecules are removed as the compressed air escapes either through a purge or naturally from leaks in the piping network. By removing moisture from the air in the pipe, the electrolyte required to complete the process of oxidation is eliminated and corrosion is slowed substantially.

This air drying technique has been used in other industries for some time. In the food and pharmaceutical industries it is vital to keep process lines clear of contaminants like those produced via corrosion as they will directly and immediately effect product. These industries operate under the principle that a pressure dew point of -15 degrees F will not only virtually stop corrosion, it will also inhibit the growth of micro-organisms.

Included with a Dry Air Pac®:

All components are pre-piped, pre-tested, and pre-wired for ease of mechanical and electrical installation on site. Each unit comes sized to fill a dry or pre-action sprinkler system to 40 psi in 30 minutes as per NFPA code, all pre-filters are included and pressure switches / pressure regulators preset to industry standards. Every Dry Air Pac® also includes a UL Listed, FM Approved Air Maintenance Device, compressor oil and vibration isolators.

Did You Know? – The FM Approval on the Dry Air Pac®; eliminates the requirement to connect the air intake to the freezer room. NFPA 13 exempts any approved packages from this costly requirement. General’s Dry Air Pac® is the only package on the market that meets this exemption.

Applications:

- Freezer Rooms

- Data Centers

- Cold Storage Facilities

- Attic Spaces

- Parking Garages

- Potential MIC Effected Areas

- Anywhere Moisture Removal is Essential

Technical Specifications

Dry Air Pac – Test and Maintenance Kits

Proper maintenance such as regular oil, filter, and desiccant inspections and replacements are vital to the life and performance of the Dry Air Pac®. If a service plan is implemented to follow these simple maintenance procedures, you can count on excellent performance and a long life for the Dry Air Pac® and its systems.

Model KAMA01 Includes replacement filter elements (3), two quarts of specially formulated compressor oil and one 50 lb. bag of replacement desiccant.

Model KSMB01 Includes replacement filter elements (3) and two quarts of specially formulated compressor oil.

Model 34006-50 Includes one 50 lb. bag of replacement desiccant.

By using the Dry Air Test Kit you can always be sure that there are absolutely no ice plugs in your air stream.

The Dry Air PacTest Kit (Model DAP-TK) is a self-contained device for visually monitoring moisture in air streams. The “Tester” consists of an adjustable needle valve. ASME safety relief valve and a sight glass gage housing containing moisture sensitive media. The media changes color in the presence of water vapor. When the media is blue, the air contains less than 20% moisture (relative humidity).

The media will change to pink when the moisture level in the air rises above 20% relative humidity. This means that ice plugs could be forming and you need to take action.

Typical installation is after an air dryer of any type, i.e. the Dry Air Pac.

Applications: The Dry Air Pac test kit is highly recommended for any facility that has multiple Dry Air Pac units running. It is designed to be a simple and immediate way to know that the Dry Air Pac is performing properly in regard to moisture removal.