South-Tek Systems Corrosion Inhibiting Solutions

Sprinkler pipe corrosion leads to costly facility damage from pinhole leaks and catastrophic losses when compromised sprinkler systems are rendered inoperable during a fire. Protect and extend the life of your fire sprinkler piping with South-Tek Systems corrosion inhibiting solutions.

Request InformationDescription

Nitrogen Generation Corrosion Solutions for Fire Protection Systems

About South-Tek Systems Technology

South-Tek Systems understands the science behind corrosion and has always been committed to ongoing testing, having provided the Fire Protection Industry with the first and longest running corrosion study of sprinkler piping exposed to both compressed air and nitrogen gas. Advise on sprinkler pipe corrosion and manufacture the most efficient and cost effective engineered corrosion solutions on the market.

As the only provider of dual-bed pressure swing absorption (PSA) nitrogen separation technology to the Fire Protection Industry, South-Tek’s nitrogen generators yield an efficient 2:1 air to nitrogen ratio versus the 3:1 ratio of competing membrane systems. Requiring less feed air to generate the same amount of nitrogen and allowing the feed air compressor to run at a lower pressure and temperature than it would in a membrane system ultimately maximizes the life of the feed air compressor and other integral components. PSA technology is also longer lasting—to the tune of 20+ years. In a PSA system, CMS material is utilized to extract oxygen from the air under pressure and capture nitrogen. It’s proven to provide 98%+ purity for longer as it does not break down nearly as quickly as the hollow fibers do within a membrane.

Wet System Corrosion Solutions

Sprinkler pipe corrosion is a serious threat for organizations that rely on wet fire sprinkler systems to protect their facilities. It leads to costly and extensive pipe repairs that can shut down or delay production in a manufacturing setting, reduce usable space in garage and warehouse settings, and force relocation of tenants or patients in residential and hospital settings.

Corrosion leads to the formation of localized pinholes and the resulting sprinkler pipe leaks can cause catastrophic property and equipment damage in facilities such as distribution centers and dormitories. More importantly, internal corrosion can cause sprinkler head blockage, reduce flow rates, and render fire protection systems completely inoperable in the event of a fire – leading to loss of life and property.

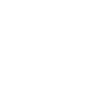

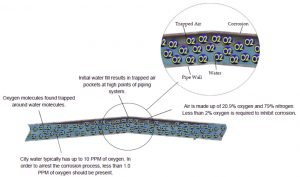

As a rule, air migrates through wet sprinkler piping to the highest points of the system, where it accumulates in pockets under compression due to the water pressure in the system. These “trapped air pockets” are comprised of 20.9% oxygen, which drives the corrosion of the interior pipe wall at the air-water interface. Another contributor to the corrosion of wet sprinkler piping comes from the highly oxygenated water that fills the system. The dissolved oxygen in the fill water reacts with the steel to form a layer of corrosive black iron oxide (magnetite) along the submerged areas of the interior pipe wall. In addition, the dissolved oxygen can transfer out of the water and into the trapped air pockets, helping to sustain the corrosion reaction at the air-water interface.

South-Tek Systems’ full suite of wet system corrosion solutions offers the right level of corrosion protection for any facility. The patent pending DeOx™ – Dual Vent O2-Release System™ provides baseline defense by helping to eliminate the corrosive air-water interface along the high points of the sprinkler pipe network. To further reduce the likelihood of electrochemical corrosion, we recommend combining the Dual Vent O2-Release System™ with the DeOx™ – N2-Inert System™. The N2-Inert System™ is designed to rapidly pre-fill any wet sprinkler system with ultra-pure nitrogen gas and effectively displace up to 99.5% of the oxygen from within the system. And for maximum corrosion protection, look no further than the Patented DeOx™ – Water DeOxygenation System™. After employing N2-Inert™ technology to target the trapped oxygen at the high points of the piping network, the Water DeOxygenation System™ then removes the dissolved oxygen and harmful bacteria from the fill water prior to it entering the wet sprinkler piping.

DeOx™ Wet Air Vent Solutions

One O2-Release system recommended per high point of piping network to eliminate corrosive air-water interface at point of installation.

DeOx™ – Single Vent O2-Release System™

- Displaces corrosive trapped air from within the sprinkler piping

- Eliminates the air-water interface, the typical location of wet pipe corrosion

- Does not create a water trap; the valve fully drains back to FPS

- Install one (1) per high point of the FPS

- Mounts horizontally on either a vertical or horizontal section of the FPS piping

- Low clearance height allows for an easy high point install

- Not to be installed in water-sensitive area

- Clearance Height: 7.65”

DeOx™ – Dual Vent O2-Release System™

Includes all of the benefits of the Single Vent O2-Release System™, plus the following:

- Dual valve provides redundancy and eliminates failure concerns

- Eliminates over spill and can be installed in water sensitive areas

- Water accumulation automatically drains back to the FPS by depressurization

- Eliminates the need for a scissor lift or ladder

- Low clearance height allows for an easy high point install

- FM and UL approved secondary air vent valve

- Secondary air vent valve can be purchased separately and added to single vent installations

DeOx™ N2-Inert & DeOxygenation Systems

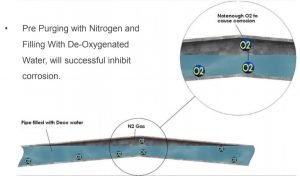

DeOx™ – N2-Inert System™

- Reduces oxygen levels within any wet FPS

- Achieves high purity N2 pre-fill within minutes

- Displaces all trapped air within a wet system with pure Nitrogen

- Reduces the air-water interface and lessens the likelihood of electrochemical corrosion developing within the sprinkler system

- Includes injection port and exhaust manifold

- Allows for up to 40 PSIG N2 fill

- Operating temperature range of 40°F – 120°F

- Fully pneumatic, no electrical required

- Easy installation and zero maintenance

- Easily integrates into a new or pre-existing FPS

- Targets both aerobic and anaerobic bacteria

- Filters particulates and removes impurities from the fill water

- Reduces oxygen content from 10 PPM to less than 1.0 PPM

- Water containing 1.0 PPM or less oxygen inhibits the corrosion reaction

- Eliminates the problematic oxygen-water interface

- Protects the installation and extends the life of the sprinkler piping

Dry & Preaction System Corrosion Solutions

Traditionally, compressed air was utilized as the source for maintaining supervisory pressure within dry and pre-action sprinkler systems. But due to the constant presence of oxygen in the compressed air, any part of the sprinkler system containing residual water left behind from hydro-testing, flow testing, or condensate accumulation is vulnerable to electrochemical corrosion.

South-Tek Systems designs and manufactures the N2-Blast® – Corrosion Inhibiting System, which effectively arrests electrochemical, galvanic, and micro-biologically influenced corrosion (MIC) by introducing up to 99.9995% pure nitrogen gas into the dry or preaction sprinkler system. The N2-Blast® also prevents ice plugs by ensuring a -40°F to -70°F dew point within the sprinkler system. As high purity nitrogen gas enters the sprinkler piping, corrosive oxygen and moisture are displaced through the N2-Blast® – AutoPurge System®.

Internal corrosion of sprinkler pipe is one of the foremost issues facing the Fire Protection industry. It leads to costly and extensive pipe repairs that can shut down or delay production in a manufacturing setting, reduce usable space in garage and warehouse settings, and force relocation of tenants or patients in residential and hospital settings. Corrosion leads to the formation of localized pinholes and the resulting sprinkler pipe leaks can cause catastrophic property and equipment damage in facilities such as data centers and museums. More importantly, internal corrosion can cause sprinkler head blockage, reduce flow rates, and render fire protection systems completely inoperable in the event of a fire – leading to loss of life and property.

Inhibiting Corrosion

The Facts on Corrosion

- Dry and pre-action systems are involved in 59% of fire losses caused by corrosion-related obstructions to sprinkler flow (FM Global)

- 73% of dry and pre-action systems inspected had significant corrosion issues after 12.5 years of normal use (VDS Study)

- Corrosion leads to property damage, ongoing pipe repair and replacement, decreased c-factor and sprinkler head blockage – potentially rendering the system inoperable in the event of a fire

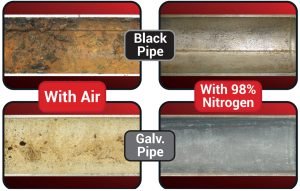

Long-Term Exposure Testing

- Long-term exposure tests are currently being conducted to compare the performance of black and galvanized steel sprinkler pipe in compressed air and nitrogen gas environments. The testing was started by South-Tek Systems and has been running continuously for more than a decade.

- The test environment is comprised of half-filled Schedule 10 black and galvanized steel sprinkler pipe sections, which are individually subjected to either compressed air, 95% nitrogen, or 98% nitrogen supervision.

Conclusions After 3,000+ Days of Uninterrupted Testing

As a result of 98% nitrogen in lieu of compressed air supervision:

Black steel: The service life of black steel pipe increases from 20 years to 63 years

Galvanized Steel: The service life of galvanized steel pipe increases from 10 years to 176 years

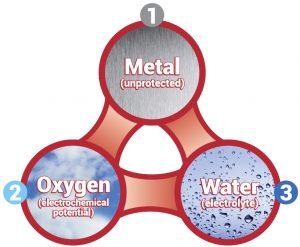

The Corrosion Triangle: 1 + 2 + 3 = Corrosion

Nitrogen eliminates the Electrochemical Potential – Oxygen (2), therefore the equation is not complete and corrosion is inhibited.

- Results in a uniform wall-thinning corrosion mechanism in black steel

- Results in a localized pitting corrosion mechanism in galvanized steel

2. Oxygen: Electrochemical Potential

- There is an inexhaustible source of oxygen in compressed supervisory air

3. Water: Electrolytes

- Come from residual water and moisture left behind after hydro test

N2-Blast Corrosion Inhibiting System

The N2-Blast® generates and introduces 98%+ pure nitrogen into the dry or pre-action fire protection system. In doing so, oxygen, a key contributor to corrosion, is displaced from the piping through the AutoPurge System®.

The N2-Blast® effectively inhibits electrochemical, galvanic and micro-biologically influenced corrosion (MIC), as well as freeze-ups and ice plugs.

The N2-Blast® – Corrosion Inhibiting System is comprised of the following:

- N2-Blast® – Nitrogen Generator

- Nitrogen Receiver/Buffer Tank

- Air Compressor and Refrigerant Dryer

- Patented AutoPurge System®

- Quick-Check® Purity Manifold or Portable N2 Purity Sensor

- Touchscreen PLC with SMART-Trak HMI

- Integral BlastOff® Series Alarms:

BlastOff I – Leak Detection System

BlastOff II – Air Bypass Alarm

BlastOff III – Early Warning System

BlastOff IV – Onboard Purity Alarm

Dual-Bed PSA Nitrogen Generators – FPS Series N2-Blast®

- Pressure Swing Adsorption (PSA) technology

- UL508A Listed Industrial Control Panel

- BlastOff™ I – Leak Detection System

- BlastOff™ II – Air Bypass Alarm

- Requires clean, dry feed air at a minimum of 125 PSI (Skid-mount Units)

- Internal refrigerated air dryer package (3,250 gal. unit and larger)

- Minimum outlet pressure of 60 PSI

- Nitrogen storage tank

- Includes (1) Quick-Check® – Portable Nitrogen Purity Sensor per project

Optional Features

- Air compressor package for N2-Blast feed air requirement & quick-fill operation

- BlastOff™ III – Early Warning System

- BlastOff™ IV – Onboard Nitrogen Purity Alarm

Specifications

- Minimum Nitrogen purity 98%

- Dew point -40° to -70° F

- Electrical 110 VAC, 5 AMPS

Wall-mount units available in 500 gallon or 900 gallon FPS sprinkler pipe capacity. Skid-mount units available from 1,650 gallons to 22,500 gallons FPS sprinkler pipe capacity.

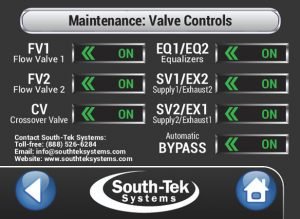

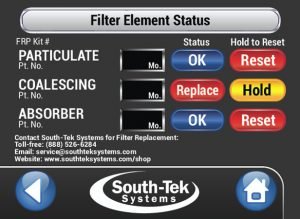

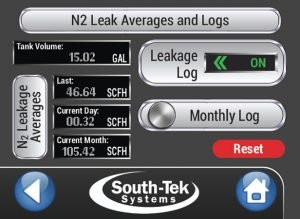

3.5” Touchscreen display (HMI) with SMART-Trak™ Software/User Interface

- Real-time status of nitrogen generator, FPS leak rate, run-time, maintenance reminders, and remote monitoring capabilities

- Ability to monitor nitrogen generator remotely via internet or app

Accessories

FACP Integration Options

South-Tek Systems developed the patented BlastOff® series of alarms to proactively ensure the longevity of not only the FPS, but the nitrogen generation system itself.

If there is a significant leak downstream or equipment malfunction that causes the N2-Blast® to run for nine (9) consecutive hours, the BlastOff® I – Leak Detection System will alarm so that the issue can be diagnosed proactively.

The BlastOff® II – Air Bypass Alarm safeguards against an install error or a technician inadvertently leaving the nitrogen generator offline.

The BlastOff® III – Early Warning System alarms if there is an issue with the equipment and/or pinpoints the location of a significant leak upstream, within, or downstream of the nitrogen generator.

The BlastOff® IV – Onboard Purity Alarm (trouble alarm) monitors the purity of the nitrogen going into the fire protection system. Trouble alarm if purity drops below 98%.

N2-Blast® – AutoPurge System®

- Cycles nitrogen continuously through FPS piping to maximize corrosion protection

- Mount horizontally on vertical section of FPS piping

- Complete with NPT connection, auto high pressure water shut-off, and adjustable AutoPurge System™ orifice

- Fully pneumatic, no electric required

- Tunable based on FPS capacity, minimizing nitrogen generator runtime

- Ensures 98%+ purity throughout FPS within (2) weeks

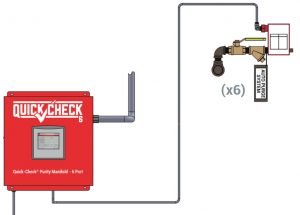

Quick-Check® – Purity Manifolds

- Samples nitrogen purity content in all zones

- Standard models: 1, 6, 10, and 20 Zone (custom models available upon request)

- Deactivates each AutoPurge System™ as the nitrogen purity set point is achieved

- Maintenance mode periodically monitors nitrogen purity in each Zone

- Equipped with 2GB micro SD card for data extraction

- Optional Ethernet communication module available for remote access

- Wall-mountable and complete with PLC and modules

- Analog 0-10V, 4-20mA signal to BMS as purity is achieved

- Electrical: 115V/60Hz/1Ph, 8 AMPS

- Provides additional location to check nitrogen purity concentration within sprinkler piping

- Offers peace of mind that nitrogen is fully blanketed throughout FPS

- One or multiple Sampling Ports can be installed on any Zone which already has an AutoPurge System™

- Mount horizontally on a vertical section of FPS piping

- No electric required

Quick-Check® – Portable Nitrogen Purity Sensor

- Battery operated, hand-held nitrogen analyzer verifies that desired nitrogen purity is achieved within all zones

- Attaches to quick connection on AutoPurge System™ or Sampling Port

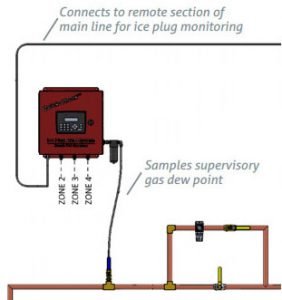

Ice Plug Alert System

- Alerts if conditions within the sprinkler piping are conducive to the formation of ice plugs (i.e. the supervisory dew point is elevated to a level in which frozen condensate occurs)

- Alerts if the main branch line is completely plugged with ice (i.e. water flow to the sprinkler head is restricted)

- Monitors up to (4) zones and provides feedback via dry contact to the building monitoring system

- Recommended for cold storage and freezer facilities, or other facilities where the sprinkler piping is exposed to freezing temperatures

- Wall mountable and complete with PLC and modules

- Electrical: 115V/60Hz/1Ph, 8 AMP